Flue-gas Desulfurization or FGD is to remove the sculpture dioxide from the exhaust gases of power plants, oil and gas industries, and major industrial plants where fossil fuel is burned. The fossil fuel industries use large exhausts that emit harmful gases into the environment. These emissions not only cause air pollution, but are also a major factor of global warming. Sculpture dioxide is the major pollutant gas which is emitted from the furnace exhausts as a result of burning fossil fuel.

It is necessary to remove the sculpture dioxide (SO2) molecules from the gas before releasing it into the open air. The method or process which is used for the removal of sculpture oxide from the gases is called the Flue-Gas Desulfurization. Fossil fuel like oil and coal produce a huge amount of sculpture compounds that react with the oxygen to form the harmful sculpture dioxide molecules. This gas must be detoxified before releasing it into air because it can be harmful to plants, animals and other living organisms.

The awareness about environmental pollution was raised in 19th century in London. Government was worried about the increasing air pollution which was causing serious health issues and causalities. The government declared these gases harmful for the humans and environment, so they started to research about this issue. In the mid of the twentieth century after almost a century, first flue gas desulfurization plant was installed in London for this purpose. After the success, these plants were used in different industries which used fossil fuel.

Nowadays, with the increasing population and to meet the energy demands, the burning of fossil fuel has significantly increased. Governments are now researching and inventing different methods for flue-gas Desulfurization. There are different methods that are used for Desulfurization of gases. The most commonly used methods are Wet Lime scrubbing, spray drying, dry lime scrubbing, Wet Sulphuric Acid Process (WSA process) and SNOX process.

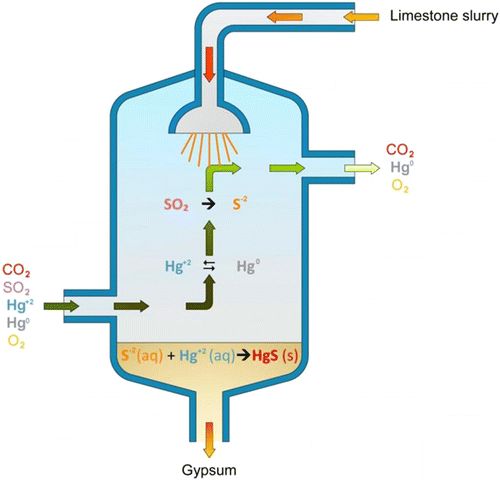

The most commonly used, effective and economical method among these is the wet lime scrubbing. More than 90% of the fossil fuel all over the world are using wet lime scrubbing for FGD. In this method, the wet lime is sprayed on the SO2 gas, which reacts and forms gypsum. The gypsum is then further treated to convert it into different metals which are then safely discharged from the plant. This method is very effective and removes more 95% of the toxic compounds.

This process requires large amounts of water. The water dissolves many toxic wastes and to neutralize the effect of these harmful metals, water must be further treated to remove these metals. Due to the limited water resources and large expenses, water is then treated again in RO plant to make it reusable. These metals are then removed from the water to ensure the reusability of water.

Many developed countries use these methods to ensure the safe discharge of water into the environment. There are strict laws imposed by the government to take measures to avoid discharge of toxic compounds into the environment. The fossil fuel industries have to install the water treatment plants and Desulfurization plants to ensure environmental safety.