In a world where product quality and safety are increasingly scrutinized, maintaining the integrity of seals on various products is essential. From food packaging to pharmaceutical products and industrial components, seal inspection plays a crucial role in ensuring that products are both safe and effective.

This article explores the importance of seal inspection, the technology behind it, and its application in various industries. For those seeking more detailed information on this topic, check out this comprehensive guide on seal inspection.

What is seal inspection?

Seal inspection is the process of examining seals on packaging and products to ensure that they are intact and functioning properly. This inspection is vital for maintaining product quality, safety, and compliance with industry standards.

Seal inspection can be manual or automated and often involves checking for gaps, leaks, and other potential defects that could compromise the seal’s integrity.

Why is seal inspection important?

The importance of seal inspection cannot be overstated. Defective seals can lead to contamination, spoilage, and even legal issues if products do not meet regulatory standards. By inspecting seals, manufacturers can detect problems early, reducing the risk of product recalls and protecting consumer health.

Furthermore, seal inspection enhances brand reputation by ensuring that consumers receive products that are safe and of high quality.

Technologies used in seal inspection

Visual inspection

Visual inspection is one of the earliest methods used for seal inspection. It involves the manual examination of seals by trained personnel. While effective, this method can be time-consuming and is subject to human error, making it less reliable for large-scale operations.

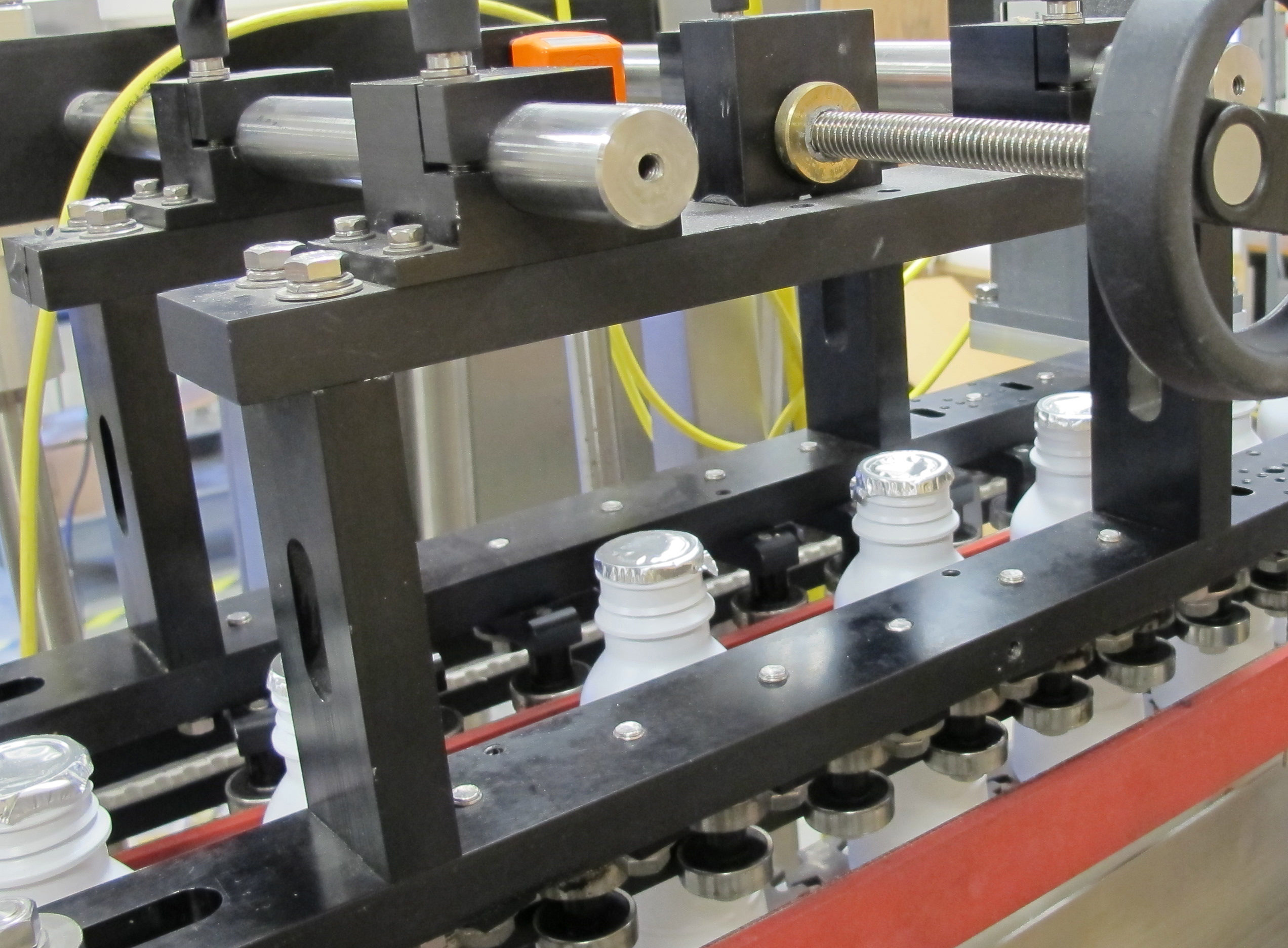

Automated inspection systems

To overcome the limitations of manual inspection, many industries are now adopting automated systems. These systems use advanced technologies such as machine vision, infrared imaging, and X-ray inspection to detect defects in seals with high precision and speed.

Automated systems are particularly beneficial for high-volume production lines, as they offer greater consistency and accuracy.

Machine vision

Machine vision technology utilizes cameras and image processing software to inspect seals. This technology is highly effective in detecting fine defects that might be missed by the human eye. It also allows for non-contact inspection, reducing the risk of further damage to the seal during the inspection process.

Infrared and thermal imaging

Infrared and thermal imaging technologies are used to inspect seals by detecting temperature variations that could indicate a defect, such as an air leak. This method is particularly useful for inspecting seals on packaging that needs to maintain a specific temperature or airtightness.

Applications of seal inspection in various industries

Food and beverage industry

In the food and beverage industry, seal inspection is critical for preventing contamination and ensuring product freshness. Defective seals can lead to spoilage and pose health risks to consumers. Automated seal inspection systems are often used to ensure packaging integrity before products are shipped to markets.

Pharmaceutical industry

The pharmaceutical industry has stringent regulations when it comes to product safety. Seal inspection helps ensure that medicine containers and packaging are secure, preventing contamination and maintaining drug efficacy. Advanced seal inspection technologies are employed to comply with industry standards and regulations.

Automotive and aerospace

In the automotive and aerospace industries, seal inspection is crucial for safety and performance. Seals in these sectors must withstand extreme conditions, and any failure could lead to critical malfunctions. Automated inspection systems are used to verify the integrity of seals in components such as engines and fuel systems.

Conclusion

Seal inspection is a vital component of quality assurance across various industries. By leveraging advanced technologies, businesses can ensure the highest standards of product safety and reliability.

From reducing the risk of contamination to maintaining regulatory compliance, seal inspection plays an essential role in protecting consumers and upholding brand integrity.

As technologies continue to evolve, the methods and precision of seal inspection are set to improve, further enhancing the quality and safety of products worldwide.