Thermal imaging sounds mysterious—almost sci-fi—but the idea is beautifully simple: everything warm leaves a trail. Mission-grade infrared systems don’t just see the world; they feel it, turning invisible heat into clarity, confidence, and faster decisions.

This is the fun part of serious technology: once you understand how thermal images work, you start seeing the world differently—day, night, rain, fog, smoke, or sandstorm.

What you might learn in this Article on Infrared Camera Tech?

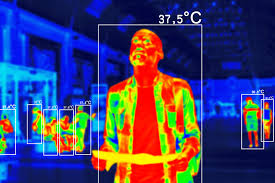

- A thermal image visualizes infrared radiation emitted by objects, revealing temperature differences invisible to the naked eye—no ambient light required.

- Thermal cameras convert infrared energy into a visible light display, allowing operators to see heat the signatures. As the temperature of an object increases, the amount of infrared radiation the object emits increases, making brighter in the IR image and easier to distinguish.

- Mission-grade systems operate in the midwave or MWIR (3–5 μm) and longwave or LWIR (7–14 μm), each optimized for different ranges and environments.

- The interpretation of thermal images is facilitated by a color palette, where each color represents a specific range of temperatures, and a processor assigns these colors to create a thermogram.

- Thermal imaging delivers its real advantage when engineered as part of a multi-sensor, AI-enabled C5ISR architecture—not as a standalone gadget.

- Optical design, signal processing, and system integration matter just as much as detector resolution.

What Thermal Energy Really Shows—and Why It Matters?

A thermal image, or thermogram, is not a photograph of visible light. It is a map of heat.

Every object emits infrared radiation. As temperature increases, the infrared radiation increases. Thermal imaging cameras detect this radiation, measure its intensity, and translate it into an image where.

Hotter objects appear in shades of white, yellow, orange, or red, while colder objects appear in shades of grey, blue, purple, or green.

That distinction is everything.

Unlike conventional cameras—which depend on reflected visible light—thermal imaging works:

- In total darkness

- Through smoke, dust, fog, and haze

- In glare, shadow, camouflage, and uneven lighting

For operators, the result is immediate and intuitive: people, vehicles, vessels, and mechanical systems pop out naturally because they displaying a unique heat signature.

MWIR vs. LWIR: Choosing the Right Infrared Band

Not all thermal images are created equal. Mission-grade thermal cameras typically operate in two infrared bands:

| Band | Wavelength | Where It Shines |

| MWIR | 3–5 μm | Long-range detection, airborne ISR, hot targets |

| LWIR | 7–14 μm | Border surveillance, ground systems, all-weather performance |

MWIR systems—often cooled—excel at long range and fast-moving targets. LWIR (long wavelength infrared) systems operate at longer wavelengths, specifically in the 7–14 μm range, and perform reliably in humidity, dust, maritime glare, and harsh weather.

The development of MWIR and LWIR technologies has led to ongoing improvements in sensitivity and detection capabilities, making modern thermal imaging systems more effective for a wide range of applications.

Both use FPA sensors (focal plane array sensors) to detect radiation in their respective infrared bands, but the choice of band determines how well the system performs across range, climate, and mission profile.

This is why system-level engineering matters more than spec sheets.

From Infrared Photon to Thermal Image (The Cool Part)

Precision Optics: Where Performance Begins

Thermal imaging starts with infrared-transparent optics, often made from materials like germanium. Optical errors that seem small on paper become mission-limiting at long range.

High-quality optical design directly affects:

- Detection range

- Resolution

- Image quality

- Consistency across production environments

Focal Plane Arrays: The Sensor’s Brain

At the focal plane, infrared radiation is converted into electrical signals using:

- Uncooled microbolometers (reliable, low power, rapid deployment, low cost)

- Cooled photon detectors (extreme sensitivity, faster response, extended range)

Uncooled thermal cameras are the most common and affordable type, widely used in handheld devices and security cameras.

Cooled detectors operate inside a vacuum-sealed case (Dewar) to maintain cryogenic temperatures—more complex, but are more sensitive and ideal for long range applications.

Signal Processing: Turning Heat Into Insight

Raw data isn’t useful on its own. Mission-grade thermal imaging devices apply:

- Non-uniformity correction

- Noise reduction

- Dynamic range optimization

- Contrast enhancement

When paired with AI, thermal images stop being “video” and start becoming actionable intelligence.

Cooled vs. Uncooled Thermal Cameras (Real-World Tradeoffs)

| Feature | Cooled Systems | Uncooled Systems |

| Waveband | MWIR or LWIR | LWIR only |

| Sensitivity | Very high (high level of performance and sensitivity) | Moderate |

| Detection range | Long (5–10+ km) | Short-to-mid (1–5 km) |

| Power & logistics | Higher | Lower |

| Lifecycle complexity | Greater | Simpler |

There’s no “best” choice—only the right system for the mission. Cooled infrared cameras are more expensive and provide superior image quality compared to uncooled cameras.

Choosing the Right Equipment for Your Mission

Selecting the ideal thermal imaging camera is about matching the device’s capabilities to your mission’s demands. Start by considering the resolution—higher resolution means more detailed images.

Sensitivity is another key factor. Cameras with higher sensitivity can detect smaller changes in temperature, making them invaluable for applications where even minor anomalies matter, such as monitoring electrical systems or ensuring operational efficiency in production environments.

The field of view determines how much area you can monitor at once. For large areas like border security or industrial sites, a wide field of view is essential. For focused inspections—such as pinpointing a fault in a particular object or component—a narrower field of view provides greater detail.

Why Thermal Imaging Beats Night Vision?

Night vision amplifies reflected light. Thermal cameras detect heat emitted directly. That difference allows thermal imaging to:

- Detect intrusions in total darkness with the ability to pick up heat signatures, even in low light or adverse weather conditions

- See through vegetation, camouflage, smoke, and fog

- Maintain performance across changing light conditions

- Operate passively—no illumination, no giveaway

Many systems combine thermal imaging with a visible light camera, giving operators both context and contrast in a single view both day and night.

Thermal Imaging Camera, The Decision Advantage

Modern operations don’t just need eyes—they need speed and confidence.

AI-Driven Detection

Thermal imagery feeds analytics that can:

- Classify people, vehicles, animals, and drones

- Suppress nuisance alarms

- Cue other sensors automatically

- Deliver prioritized alerts

Sensor Fusion

By combining thermal, visible, radar, and metadata, multi-sensor systems dramatically reduce false alarms while increasing detection probability—especially across large areas.

This is where companies like Clear Align focus their work: designing advanced thermal imaging cameras not as isolated devices, but as critical components inside integrated EO/IR and C5ISR platforms used for borders, maritime security, and critical infrastructure protection.

Where Thermal Imaging Delivers Real-World Impact compared to Visible Light Cameras

- Border & Perimeter Surveillance – Persistent detection, low false alarms, all-weather reliability

- Defense & Counter-UAS – Long-range ISR, base security, drone detection

- Maritime Security – Spotting small vessels and swimmers against cooler water

- Industrial & Infrastructure Monitoring – Electrical and mechanical systems, building diagnostics, predictive maintenance

Understanding the Limits of Infrared Radiation—and Engineering Past Them

Thermal imaging is affected by emissivity, ambient temperature, humidity, and weather. The best systems compensate through:

- Spectral band selection

- Advanced optical design

- Intelligent processing

- Multi-sensor integration

That’s how thermal imaging devices maintain accuracy when standalone cameras struggle.

Best Practices for Better Thermal Images

- Calibrate thermal cameras regularly sometime called a NUC or Non uniformity correction to adjust for environmental temperature changes

- Use high-resolution imaging devices for fine detail and to enable AI

- Combine thermal images with visible light for full context

What’s Next for Thermal Imaging?

Thermal imaging technology is evolving fast:

- New sensor materials increase sensitivity, reflecting ongoing development in infrared detection technology

- AI and machine learning enable real-time detection and enhance the ability of thermal imaging systems to evaluate signals and connect with other devices

- Improved cooling boosts range and image quality and long term reliability

- Civilian use expands alongside security applications

From autonomous systems to scientific research, thermal imaging continues to grow in relevance and capability.

Closing Perspective

Thermal imaging is no longer just about seeing heat. It’s about turning heat into decisions.

When thermal cameras are engineered as part of an integrated EO/IR and C5ISR system—combining optics, sensors, processing, AI, and deployment—they become a decisive advantage across security, defense, and infrastructure missions.

In a world where visibility is never guaranteed, thermal images reveal what the eye cannot—and that changes everything.