Managing manufacturing processes efficiently is challenging. Production planning software for manufacturing offers solutions to streamline operations and enhance productivity. This article explores how this software can improve your production scheduling, resource management, and overall efficiency.

Key Takeaways

- Production planning software is essential in manufacturing for optimizing processes, improving efficiency, and aligning output with market demands.

- Key benefits include enhanced resource utilization, improved inventory management, and better production scheduling, all contributing to increased operational efficiency.

- Top software solutions like NetSuite, Epicor Kinetic, and OpenBOM provide comprehensive features for real-time data access, scenario analysis, and CAD integration, enhancing production planning effectiveness.

Importance of Production Planning Software in Manufacturing

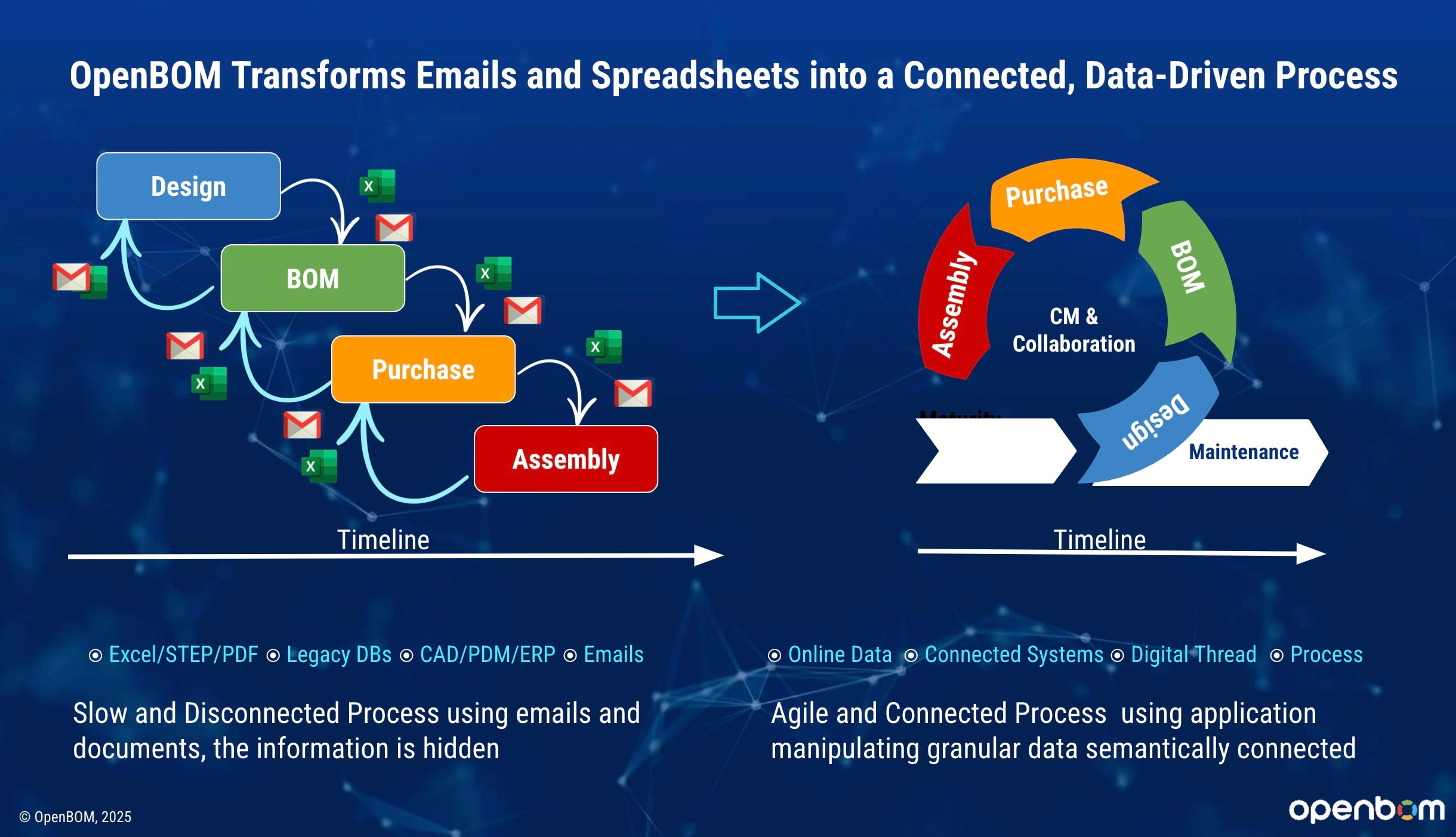

In the complex world of manufacturing, production planning software is indispensable. It optimizes processes by integrating various functions to create streamlined operations, ensuring smooth and efficient production.

Imagine the chaos of managing production schedules, inventory, and resources manually; this software simplifies these tasks, aligning output with market demands and enhancing efficiency. This alignment boosts customer satisfaction and keeps manufacturing operations on point.

Effective production planning software reduces production bottlenecks, ensures resource availability, and maintains product quality within budget constraints. Think of it as the backbone of your operations, helping you navigate production complexities with ease.

These tools enable manufacturers to achieve peak efficiency, adapt rapidly to market changes, and remain competitive in an evolving industry.

Additionally, production planning software helps create a master production schedule aligned with production capacity and customer demands to predict demand. This ensures you meet and exceed expectations, leading to increased customer satisfaction and loyalty.

Production planning software is crucial for unlocking your production potential and driving your production plans forward.

Production managers can greatly benefit from these tools in their production management efforts, especially when addressing production issues. Additionally, production scheduling software can enhance the efficiency of these processes.

Key Benefits of Implementing Production Planning Software

Implementing production planning software in manufacturing offers numerous benefits, including increased operational efficiency, enhanced inventory management, and improved production schedules.

Here are key benefits and how they can transform your manufacturing processes.

Enhanced Resource Utilization

Production planning software optimizes resource utilization, ensuring efficient use of material and human resources. By minimize waste and costs, it significantly increases profits and overall production efficiency through enterprise resource planning.

Material Requirements Planning (MRP), part of many production planning tools, ensures timely material availability, reducing delays and enhancing efficiency by keeping the right amount of material resources on hand.

Resource capacity planning optimizes asset usage by identifying potential issues early and allowing necessary production adjustments.

These elements ensure every resource is utilized to its full potential, contributing to maximum efficiency in manufacturing operations and effective resource allocation to optimize resource allocation and manage resources.

Improved Inventory Management

A standout benefit of production planning software is its ability to improve inventory management. By aligning inventory levels with production needs, these tools reduce waste and ensure efficiency. Detecting inconsistencies and limiting bad parts and material waste are crucial for maintaining quality standards and minimizing costs.

Production planning software lowers inventory costs by maintaining optimal stock levels, preventing excess or insufficient inventory.

Materials requirement planning ensures the availability of raw materials needed for production, assisting in effective inventory management. The goal is to keep stock levels low while meeting production demands.

Additionally, these tools monitor materials and products throughout the production process, preventing excess inventory and minimizing risks. For plant managers, this means better control over inventory levels, reduced waste, and timely deliveries, contributing to operational efficiency and effective inventory control.

Better Production Schedules

Efficient production schedules are critical for meeting customer demands and maintaining smooth operations. Production planning software creates production scheduling that aligns with both customer demands and operational capabilities.

Real-time data allows manufacturers to make timely decisions, ensuring orders are met and resources are available when needed.

Production sequencing organizes tasks to enhance workflow speed and prevent delays. Optimized schedules ensure efficiency, reduce waste, and help fulfill customer expectations promptly, leading to increased customer satisfaction and loyalty.

Top Features of Production Planning Software

Top production planning software comes with features designed to enhance productivity and streamline operations. Key features include real-time data access, scenario analysis, and CAD tool integration.

Here’s how these features contribute to more efficient and effective production planning.

Real-Time Data Access

Real-time data access is crucial for modern manufacturing efficiency. Production planning software provides insights that facilitate better-informed decisions. This visibility into inventory, orders, and production schedules helps manufacturers stay agile and responsive to changing conditions.

For instance, SAP S/4 HANA and NetSuite offer advanced capabilities for real-time process management and analytics, ensuring data is always up-to-date and accessible. This ease of data analysis leads to more efficient production and higher operational efficiency.

Scenario Analysis

Scenario analysis is an invaluable feature, allowing manufacturers to test different production scenarios for better planning and decision-making. By evaluating various situations, manufacturers can prepare for different outcomes and handle any eventuality.

This feature aids in optimizing planning and workflow automation, providing detailed reports for informed decision-making. Ultimately, scenario analysis contributes to a more resilient and adaptable manufacturing operation.

Integration with CAD Tools

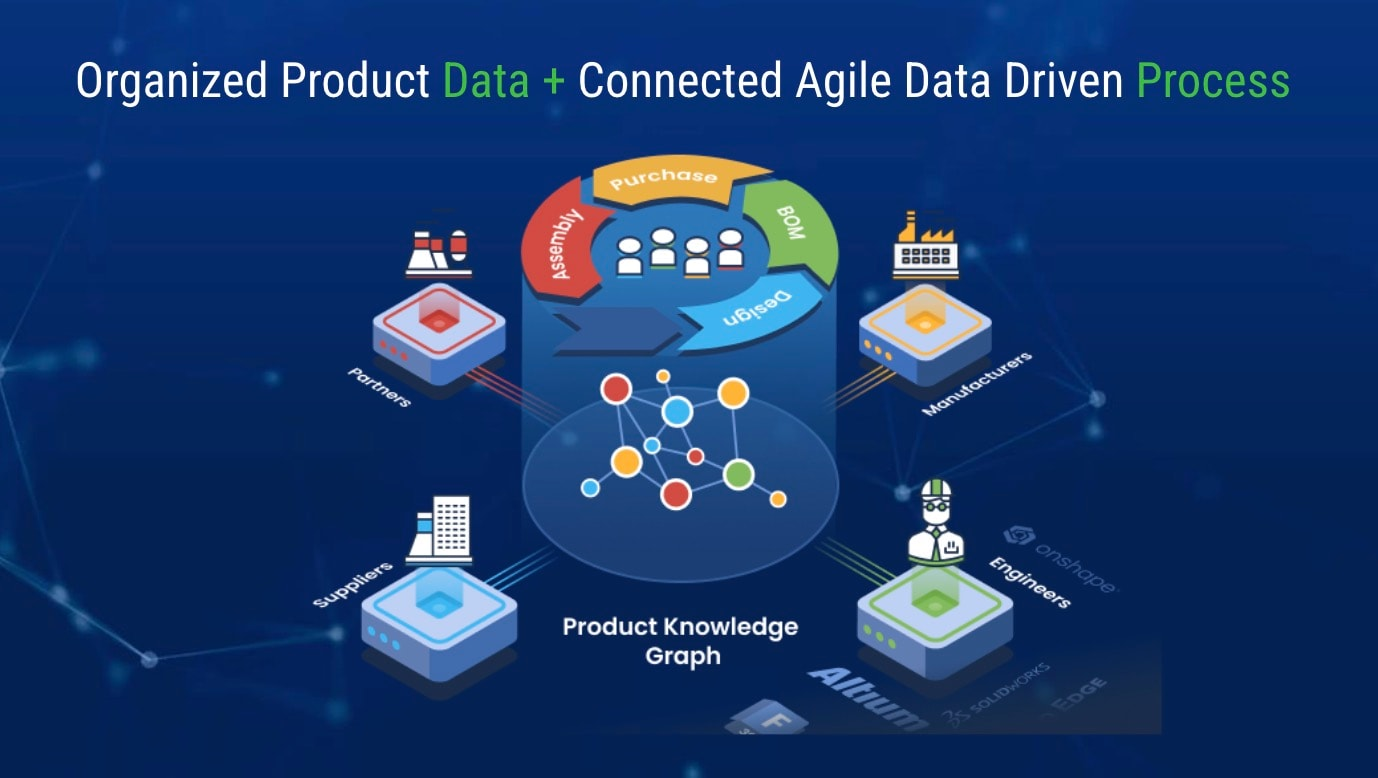

Seamless integration with CAD tools is another critical feature. This integration enhances data transfer, improving production planning accuracy and reducing manual data entry errors.

For example, OpenBOM integrates with CAD systems like SolidWorks and Fusion 360, enabling users to generate and update BOMs in real time without exporting or re-entering data.

This integration between CAD and ERP systems improves data accessibility and facilitates collaborative product data management, allowing teams to share item catalogs and inventory easily. A user-friendly interface ensures these processes are intuitive and easy to navigate, enhancing operational efficiency.

Leading Production Planning Software Solutions for Manufacturers

Several production planning software solutions stand out for their robustness and efficiency. Notable among these are NetSuite, Epicor Kinetic, and Infor CloudSuite Industrial. These solutions offer comprehensive features that cater to diverse manufacturing business needs, ensuring efficient production planning and scheduling.

Each software solution brings unique capabilities. NetSuite provides real-time visibility into inventory, orders, and production schedules, while Epicor Kinetic and Infor CloudSuite Industrial offer advanced features for resource planning and workflow automation.

These tools enhance production performance and operational efficiency, which increases efficiency, making them invaluable for any manufacturing business looking to optimize operations.

OpenBOM

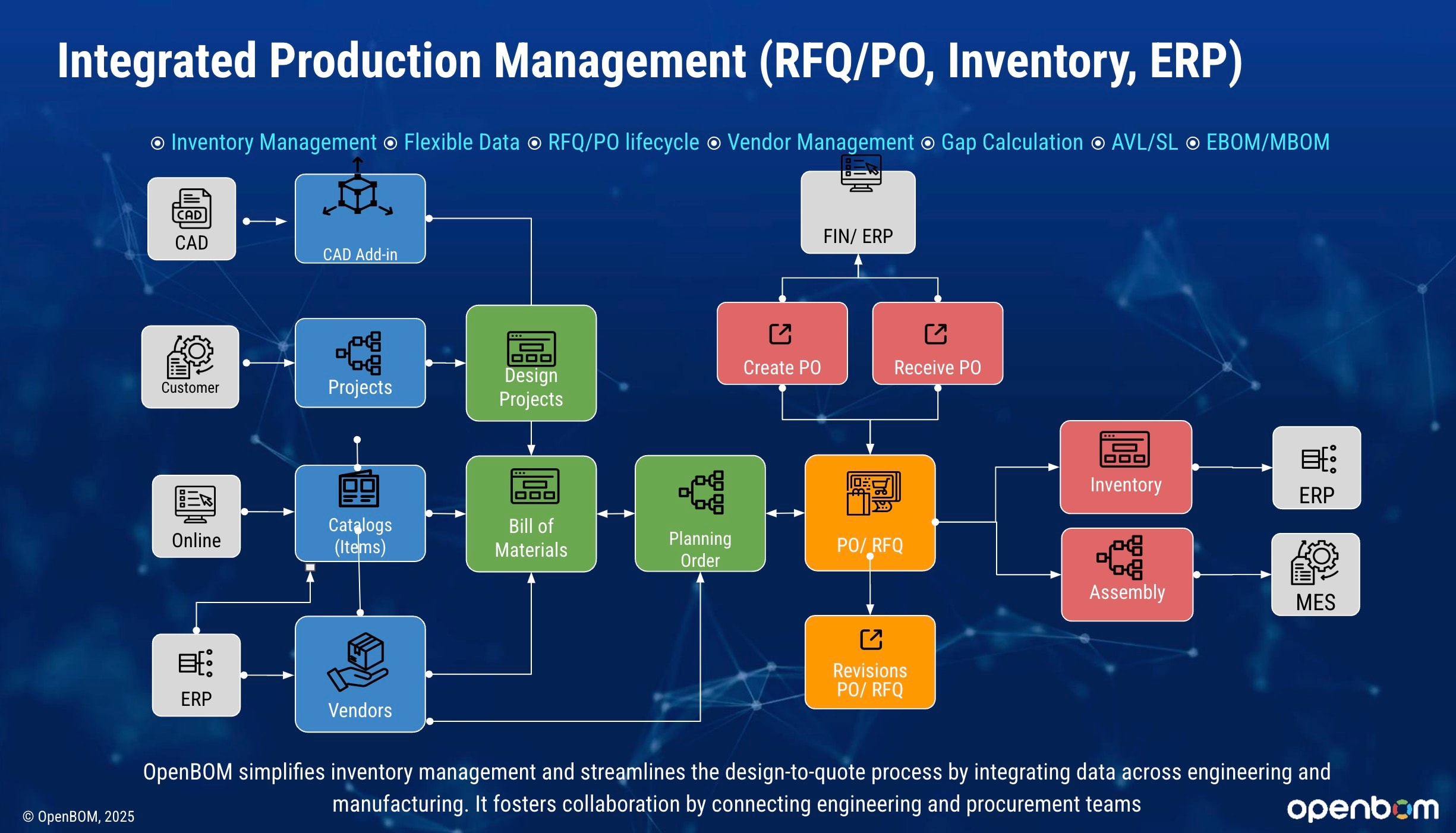

OpenBOM is a cloud-native solution connecting engineering, procurement, and inventory management into a single, real-time workflow. It provides:

- Live item catalogs with vendor and supplier data

- Multi-level engineering BOMs

- Tools for creating RFQs and purchase orders

- Real-time inventory tracking

- Smooth release to production—all in one place

This comprehensive approach ensures seamless integration of all production planning aspects, facilitating efficient processes.

OpenBOM’s production planning includes:

- Inventory management via ‘Catalog Quantity on Hand,’ ensuring optimal inventory levels.

- Release to production for final assembly.

- Consumption of all components.

- Updating inventory by decreasing the quantity on hand.

These steps ensure a smooth and efficient production process with the goal of managing the inventory of all company items effectively, optimizing production processes.

OpenBOM includes robust vendor management features, allowing users to:

- Manage vendor and supplier lists

- Streamline the creation and receipt of RFQs and purchase orders, making BOM planning for purchase more efficient

- Seamlessly integrate with Bill of Materials functionality, allowing smooth data handover between engineering and purchasing departments, further enhancing production planning.

How to Choose the Right Production Planning Software?

Choosing the right production planning software involves considering your business needs, budget, and the software’s user-friendliness. Evaluate the features, costs, and how easily the software can be adopted by your team.

Here’s a detailed look at these aspects to help you make an informed decision.

Assessing Your Business Needs

Identifying specific business requirements and production goals is crucial for selecting effective production planning software.

Understanding your manufacturing business’s challenges will help identify the right software functionalities to address these issues. For example, if managing inventory is a primary challenge, look for software with robust inventory management features.

Costs associated with production planning software can vary based on features, user numbers, and deployment types (cloud versus on-premises). Factor in ongoing maintenance and support costs to ensure the software remains effective and within budget.

Budget Considerations

When selecting production planning software, consider your budget. Prices can vary widely; for example, advanced systems like Plex Cloud ERP can cost over $3,000 a month, while simpler solutions like MRPeasy start at $49 per user per month. Balance features and costs to ensure the software meets your production needs without straining your budget.

Understanding costs associated with production planning software will help your business remain competitive and efficient. Consider scalability and ongoing costs to ensure the software meets future demands.

Evaluating User-Friendliness

A user-friendly interface is essential for effective use of production planning software. When users can easily navigate the software, how many users adopt it increases, leading to more efficient manufacturing processes. Intuitive design, clear labeling, and responsive customer support significantly enhance the user experience.

Providing comprehensive training and ongoing support is vital for maximizing the benefits of production planning software. Ensuring your team is comfortable with the software will lead to higher operational efficiency and better overall production performance, keeping production running smoothly.

Case Study: Successful Implementation of OpenBOM

A real-world example of OpenBOM’s successful implementation showcases its benefits and improvements in manufacturing efficiency. One company used OpenBOM to manage multiple BOMs, ensuring synchronized and relevant data for engineering and manufacturing teams. This synchronization reduced errors and improved production timelines.

OpenBOM’s API allowed the company to customize workflows and automate repetitive tasks. This automation facilitated smoother communication across departments, further enhancing production efficiency.

The platform’s support for change control processes ensured that revisions were validated before entering the ERP system, maintaining high-quality standards.

These features collectively enabled the company to operate more efficiently, reducing errors and improving production timelines. OpenBOM proved to be an advanced tool designed to enhance production efficiency through better management of bill of materials (BOM).

Summary

In summary, production planning software plays a crucial role in optimizing manufacturing operations. It enhances resource utilization, improves inventory management, and ensures better production schedules.

Leading solutions like OpenBOM offer comprehensive features that integrate engineering, procurement, and inventory management into a seamless workflow.

Choosing the right production planning software involves assessing your business needs, budget, and user-friendliness.

By implementing the right software, manufacturers can achieve higher efficiency, reduced costs, and improved customer satisfaction. Embrace the power of production planning software to drive your manufacturing business forward.

Frequently Asked Questions

What is the importance of production planning software in manufacturing?

Production planning software is crucial for optimizing manufacturing efficiency by aligning production with market demands, minimizing bottlenecks, and ensuring resource availability, ultimately maintaining product quality and adhering to budget constraints.

How does production planning software enhance resource utilization?

Production planning software enhances resource utilization by optimizing asset usage and ensuring timely materials availability, which reduces waste and costs while increasing efficiency and profits. This leads to more effective management of resources throughout the production process.

What are the key features of production planning software?

Production planning software should offer real-time data access, scenario analysis, and integration with CAD tools to enhance decision-making, improve data accuracy, and minimize manual errors. These features are essential for efficient manufacturing operations.

How does OpenBOM integrate with CAD tools?

OpenBOM integrates seamlessly with CAD tools such as SolidWorks and Fusion 360, allowing users to generate and update Bills of Materials (BOMs) in real time, which enhances production planning accuracy.

What should be considered when choosing production planning software?

When selecting production planning software, prioritize your business needs, budget, and user-friendliness while also evaluating features, costs, scalability, and support. These considerations will ensure the software effectively meets your current and future production requirements.