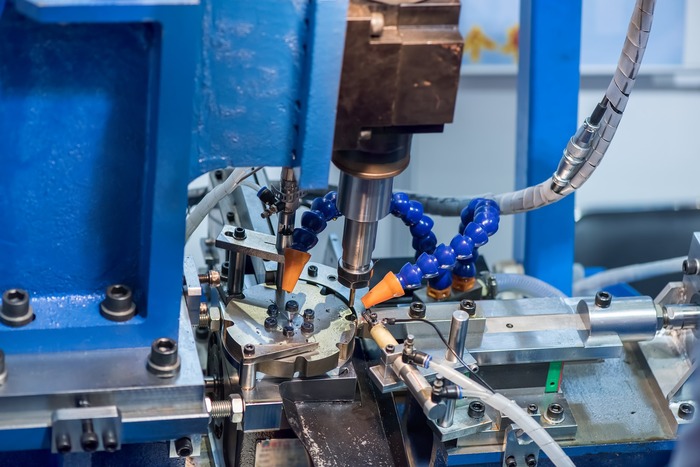

Swiss CNC machining is an advanced manufacturing method that is known and loved for its high level of precision. Also known as a Swiss-type lathe or sliding head lathe, Swiss CNC machining comprises several components that work in synergy to create precise and intricate small parts.

This high-level manufacturing technique has applications in a wide range of fields. It’s most commonly used in the automotive world, aerospace sector, and medical field, where precision and accuracy are essential.

How Does Swiss CNC Machining Achieve High-Level Precision?

There are several factors that contribute to the unparalleled precision of Swiss CNC machining, including those discussed below.

Unique machine design

Swiss CNC machining has a unique design that sets it above other manufacturing machines. This unique design enables manufacturers to achieve an incomparable level of precision when producing materials.

Unlike conventional machining designs, Swiss CNC machines utilize a sliding headstock and a guide bushing. These features enable the machinery to move along an accurate route through the material, resulting in intricate, consistent, and precisely cut products.

Low tool runout

Tool runout refers to when a machine deviates from its true path during rotation. Deviation can affect the precision of the resulting product and lead to defects or malfunctions.

Swiss CNC machining is designed to have minimal tool runout to ensure a high level of precision, accuracy, and detail during the cutting process. It uses a tool clamping system that eliminates undesired movement in the cutting machinery, resulting in consistent and precise final materials.

Guide bushing

The use of guide bushing technology in Swiss CNC machining contributes to its high-level precision. Guide bushing offers additional support for the material that is being processed by the machinery, keeping it stable throughout.

With this extra support and stability, the material remains stationary with little vibrational movement or deviation as the Swiss CNC machinery moves along it. This results in intricate cutting and precise processing that is difficult to achieve with standard machining methods.

Automatic bar feeding

Swiss CNC machining often has an integrated automatic bar feeding system, which allows for the continuous and uninterrupted processing of materials. Automatic bar feeding uses long bars that enhance efficiency and enable more than one material to be processed from a single bar.

As a result, Swiss CNC machining promotes modern manufacturing efficiency, accuracy, and precision. It also reduces waste production and energy consumption, making machining processes more sustainable in the long term.

Closed-loop feedback system

Another component of Swiss CNC machining that contributes to its high precision and accuracy is the integrated closed-loop feedback system. This system continuously monitors multiple aspects of the machining process to ensure it remains consistent.

Closed-loop feedback systems can monitor cutting parameters, tool position, and feed rate in real time. If one of these factors deviates from its optimal, the sensors within this system will signal to the central machining mechanisms to adjust the machinery appropriately. With rapid and real-time responses, the Swiss CNC machining process offers a very low risk of error and ongoing precision.