Robotic printing is an innovation with immense potential for revolutionizing industries. Integrating robotics in printing processes offers exciting possibilities, from 3D printing of building components to automated construction site tasks. As the construction and engineering industries continue to evolve and grow, future technology in construction is bound to transform the way projects are designed, planned, and executed. This article will explore the future trends in robotic printing, the innovative technologies driving these advancements, and the potential applications in the construction and engineering sectors.

The Evolution of Robotic Printing in Construction and Engineering

Advancements in 3D Printing Technology

In recent years, people have experienced remarkable progress in 3D printing technology. Its impact is far-reaching, spanning from prototyping to personalized manufacturing. What’s genuinely awe-inspiring is the way 3D printing is reshaping the construction landscape, breathing new life into buildings and infrastructure. It’s a groundbreaking innovation with immense potential to revolutionize these industries as people know them.

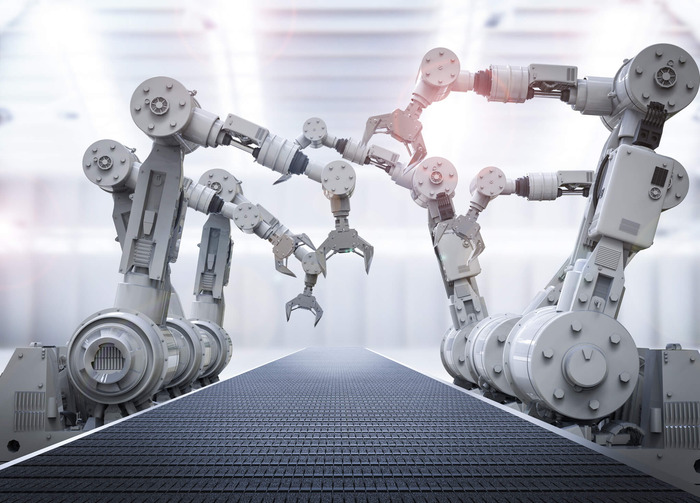

Robotic printers equipped with 3D printing capabilities can create complex architectural elements, structural components, and even entire structures. This technology allows for greater design freedom, reduced material waste, and faster construction timelines.

Automation and Site Integration

Future trends in robotic printing emphasize integrating these systems into construction sites. These robots can collaborate with human workers, automating repetitive tasks and improving overall productivity.

These printers can be programmed to handle material handling, bricklaying, and concrete pouring. This automation reduces labor requirements, enhances accuracy, reduces construction time, and minimizes the risk of human error.

Modular Construction and Prefabrication

The future of construction embraces modular construction and prefabrication techniques, and it plays a crucial role in facilitating these methods. These printers can precisely create prefabricated building components, enabling faster assembly and on-site construction.

These printers in modular construction allow for consistent quality control, customization, and efficient use of materials. This results in cost savings, reduced construction time, and enhanced sustainability.

Potential Applications of Robotic Printing in Construction and Engineering

Large-Scale 3D Printing of Buildings

It is capable of large-scale 3D printing have the potential to revolutionize the construction industry. With the ability to create intricate architectural designs and complex structural elements, 3D printing can enable faster and more cost-effective construction of buildings.

Large-scale 3D printing offers reduced labor requirements, minimal material waste, and the ability to create unique and sustainable designs. This technology opens up possibilities for innovative architectural forms and efficient construction processes.

On-Site Customization and Adaptability

It allows on-site customization and adaptability, catering to specific project requirements. Robots can precisely fabricate building components based on real-time design modifications and site conditions, resulting in efficient and tailored construction solutions.

The ability to adapt to changing design needs and optimize construction processes in real-time can significantly improve project outcomes and client satisfaction.

Infrastructure and Disaster Relief

It can potentially revolutionize infrastructure development, particularly in remote or disaster-stricken areas. Robots can be deployed to construct bridges, roads, and other critical infrastructure swiftly and efficiently.

In disaster relief scenarios, robotic printers can quickly produce temporary shelters and housing units, providing immediate relief to affected communities. This technology offers a rapid and cost-effective solution for post-disaster reconstruction.

Conclusion:

Among the various future trends in robotic printing, integrating 3D printing technology and automation in construction holds immense potential for transforming the industry. From large-scale 3D printing of buildings to on-site customization and adaptability, these innovations promise faster construction, reduced costs, and enhanced sustainability.

By embracing robotic printing technologies, the construction and engineering industries can benefit from increased efficiency, improved safety, and reduced environmental impact. The ability to automate repetitive tasks, customize designs, and construct complex structures with precision can revolutionize how projects are executed.

As the future technology in construction unfolds, it will play a vital role in shaping the industry, unlocking new possibilities, and pushing the boundaries of what is achievable. The potential applications and innovations hold the key to creating sustainable, efficient, and visually stunning structures that meet the evolving needs of our built environment.