One of the most difficult challenges in logistics is the successful transportation (and storage) of goods that have special temperature requirements. As it turns out, many different industries rely on precise temperature-controlled logistics, such as healthcare, pharmaceutical, food, and the beverage industry.

This is a mission-critical matter for the companies responsible for these types of goods, as spoiled products can have severe consequences on the health and well-being of the consumer. Furthermore, companies must abide by several standards and regulations, especially when it comes to the transportation of healthcare and life science products such as vaccines or medication.

Fortunately, advancements in technology provide companies with a myriad of solutions that equip relevant teams with up-to-date information on the status of their goods right through the entirety of their supply chain. This gives businesses the ability to react to changes in circumstances that may affect the quality of the product, which helps to save on costs associated with spoiled shipments and dissatisfied customers.

What is a temperature notification system?

Companies must understand how quickly their products lose their initial quality when taken outside of their recommended temperature ranges. As mentioned above, spoiled products can be extremely detrimental to the end consumer. Organizations may face heavy fines and serious repercussions if they fail to ensure adequate temperature control.

This is why it’s critical to track how long a product has been held at an incorrect temperature, on a reliable data timeline.

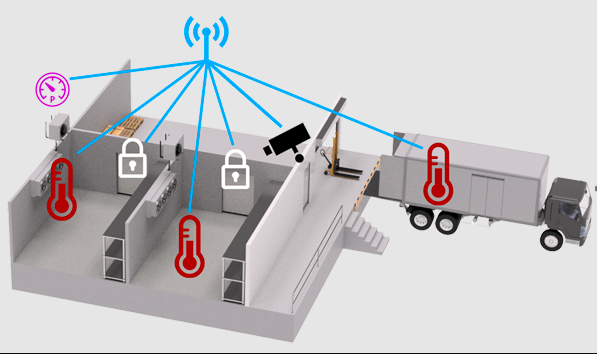

Fortunately, a temperature notification system can help in this circumstance, as it allows businesses to quickly track, control, and adjust the temperature of goods in a controlled environment, ensuring that temperature-sensitive products remain safe and undamaged throughout their journey.

Advanced systems like these provide organizations with:

- Real-time data on the temperature of goods in transit

- Automatic alerts when the temperature falls out of a predetermined range

- Data-driven reports that can be analyzed for further insights

- Notifications at key fail points along the supply chain

On that note, let’s take a look at three key use cases for temperature notation systems when used in logistics:

Real-time notifications of equipment failures and other unexpected events

When mechanical breakdowns, traffic delays, and other issues cause a break in the cold chain, the result is often temperature fluctuations that could compromise perishable goods and cause them to spoil. However, one of the main reasons goods tend to deteriorate in these instances is that the relevant departments are only informed of these events once it’s already too late.

Thanks to temperature notification systems, teams can stay informed about the temperature of the goods 24 hours a day, seven days a week.

No matter what stage of transit the cargo is in, these systems allow the set up of automated alerts, custom indicators, and real-time reporting. Knowing about a temperature spike as soon as it starts – and which shipments may be affected – is invaluable information that helps businesses make better decisions about the measures they need to take with their shipments.

As a result, temperature monitoring systems are a fantastic tool to help companies to mitigate risk, reduce waste, and avoid unnecessary costs.

Reducing excessive use of freezing technologies

Refrigeration is a crucial component of cold-chain logistics because it delays the rate at which food and other perishable items deteriorate. Companies go to considerable efforts to ensure their items remain cooled throughout their entire transit, which is why an efficient and effective cold chain is intended to provide the optimum conditions for delaying or avoiding these changes for as long as it is possible.

However, cooling systems are not only costly to run and maintain for the businesses that employ them, but most cooling technologies are also very damaging to the environment. This is because maintaining the cold chain necessitates energy, and the production of that energy adds to CO2 emissions and climate change.

With this in mind, we must avoid excessive use of freezing elements and take the environmental impact of cold chain logistics into account. Temperature notification systems help companies to refrain from “over-cooling” their products as they can continually monitor the temperatures of their cargo remotely.

Without this information, organizations would be more inclined to cool their products to a lower temperature than what is actually required to give themselves a margin of error. Thus, using a temperature notification system means companies will have more confidence to keep their products refrigerated within more reasonable parameters using real-time data and automatic alerts.

Assisting drivers who transport temperature-sensitive goods

A temperature monitoring system hugely benefits the people who are actually carrying the goods, which in most cases is the drivers of the trucks and the cargo vehicles that house the temperature-controlled items.

If the cargo is fitted with a temperature notification system, drivers will have access to important information about the goods they are carrying, which allows them to make more informed decisions along their journey.

With up-to-date knowledge of the status of temperature-sensitive goods, drivers can tailor their journey and base their decisions around the needs of the product. This may affect things like the route they choose to take, the length, location, and duration of the place where they park the vehicle, or whether or not they stop to take a break at any given time.

Furthermore, the temperature notification system will inform the driver if there are any issues with the shipment they carry or mechanical issues with the refrigeration unit. In these instances, when the temperature control system fails, the driver can quickly identify the problem and alert the relevant people, giving them a much better chance at saving the shipment from spoiling.

Final word

Temperature-sensitive goods are difficult to transport, especially for businesses operating complicated supply chains. With that said, having precise temperature data addresses numerous logistical issues and helps to reduce the loss of perishable goods such as food and pharmaceuticals.

Temperature notification systems offer companies access to valuable information such as when something goes wrong with their shipment and how many units the temperature increased or decreased. With this data, businesses can react more quickly to incidents and perhaps prevent shipments from deteriorating, reducing costs and protecting revenue.