Indisputably, the emergence of flexible packaging in the food industry has ushered in a new age of profitability for businesses. Cheese products aren’t left out of this revolution and flexible cheese packaging is the way to go in this line of business. Like none other, this packaging option encourages the production of high-quality pouches that offer outstanding barrier protection against mold-friendly gases and other contaminants that can compromise cheese quality while in storage.

If you are still in doubts on whether to opt for flexible materials in your cheese production line, here are a few reasons to join the wagon.

Myriad of Options

On its own, flexible packaging provides a wide range of options and formats that cheese manufacturers can employ creatively.

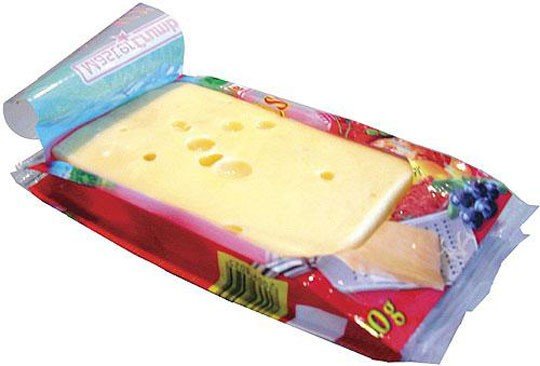

Packaging options include paper composites, cheese foils, films, wrapping films, lidding films for spreadable cheeses; flow packs and pouches for grated cheeses and thermo-formed packs for slices.

Unlike the rigid packaging materials, flexible materials allow businesses to play around and adopt the final product to suit their brand and style. Flexible packaging companies customized packaging products for different companies as per the requirements.

Moreover, the option to include re-seal or re-close functionalities adds to the appeal and usefulness of these packs.

Less Packaging Cost

It is unusual for innovative ideas and creations to come cheap at the onset but the reverse is the case with flexible packaging.

Cheese companies employing flexible packaging have been found to spend less in production compared to other brands utilizing bottles, cartons and other popular rigid structures in their packaging.

The reasons aren’t far fetched as the material required for the production of flexible materials are not only more readily available but also cheaper to acquire.

Furthermore, the near weightlessness of flexible materials ultimately leads to a reduction in the costs accrued from shipping and distribution to the end users.

Improved Shelf Life

Cheese and other dairy commodities are able to take advantage of flexible packaging’s barrier protection to improve on their shelf life.

The airtight nature of this packaging inhibits any form of fungal or microbial growth from contaminating the packaged cheese over extended periods of time.

This protection is equally effective against water vapor, light, and external aromas, thus, creating the perfect atmosphere for the preservation of freshness over time.

On the other end, a different gauge of flexible material can be used to provide additional breath ability for soft cheeses which need to continue to maturity in the pack.

Innovative Branding Options

Flexible packaging companies have harnessed the branding potentials of flexible materials to drive cheese sales.

It is not strange that the attractiveness, design, color and unique shape of cheese packages provide visibility that draws customers to them.

Beyond doubts, cheese makers want the most attractive branding options and flexible packaging is the direction to follow.

Considering that 3D printing and many similar innovative technologies have been optimized to work out of the box with flexible materials, there is no escaping the competitive advantage of utilizing flexible packaging in marketing and product branding.

Easy Recycling

An increasing number of top brands are refreshing their product packages and adopting flexible packaging in a move to make the world a safer place.

This is one reason to not hesitate and make the switch to flexible packaging for your cheese products. The environmental impact of many flexible materials is unparalleled and the eco-friendly nature of this packaging option is why there is a high rate of adoption.

The ease of recycling makes it easy for cheese manufactures to reuse the materials over and over.

More importantly, flexible packaging reduces the level of environmental degradation because much less damaging materials are used in production.