With the advancement of technology, robots are fast taking over the role of human labor. Industrial automation is the utilization of automatic control gadgets and certain technologies to execute automatic tasks, and regulate industrial procedures. While these procedures do not necessarily require human intervention, they are more functional as compared to manual control.

Industrial automation structures are naturally intricate especially because they involve the collaboration of automation technologies and numerous other gadgets. There are various levels of the automation structure. These are;

Field Level

This is the lowest level in the order of automation. It involves field devices such as actuators and sensors. The principal role of the field gadgets is to move machines and data of procedures to the subsequent level for the execution of analysis and supervision. In addition, the actuators make way for the regulation of parameter procedures. This level can also be referred to as the arms and eyes of a specific procedure.

The role of the sensors is to modify actual parameters such as flow, pressure, temperature, and level into electrical indicators. The sensor data is subsequently moved to the controller in order to facilitate analysis and supervision of the actual parameters. These sensors include; RTDs, thermocouple, flow meters, and proximity sensors.

Elsewhere actuators change the electrical indicators to mechanical means in order to aid the regulation process. Actuators include; solenoid valves, relays, pneumatic actuators, flow control valves, servo motors, and DC motors.

Control Level

This level comprises of different automation gadgets such as PLCs and CNC machines. These obtain the procedure parameters from different sensors. Automatic controllers move the actuators depending on the produced universal robotics sensor indicators and regulation or program technique.

PLCs (Programmable Logic Controllers)

Programmable logic controllers are commonly used powerful industrial controllers. They can transmit automatic control functions depending on the sensor input. It comprises of different modules such as digital I/O, analog I/O, CPU, and communication parts. With these, the operator can program a regulation plan or function to carry out a specific automatic operation.

Monitoring And Production Control Level

At this level, both monitoring structures and automatic gadgets promote collaboration and regulation roles such as HMI (human machine interface), historical archiving, monitoring different parameters, setting machine shutdown and start, and setting production goals. Often, SCADA (supervisory control and data acquisition) or DCS (distribution control system) human machine interface are used at this level.

Enterprise Or Information Level

Enterprise is the highest level in industrial automation and it controls the entire automation structure. This level comprises of duties such as outlining of production, sales and orders, and market and customer evaluation. Basically, this level involves fewer technical aspects and more commercial activities. In addition, industrial communication systems are more important in industrial automation structures.

This is because they pass information from one level to another. This means that they can be found on each automation structure level to facilitate constant information flow. This communication system can vary from one level to the other. These systems include; profibus, DeviceNet, RS485, Foundation Fieldbus, and CAN.

The conclusion we can derive from the above order of industrial automation systems is that there is constant flow of information from the lowest level to the highest level.

Examples Of Industrial Automation Systems

- Programmable Automation

This involves procedural operations, assembling, and product changes which can be executed with adjustment of the regulation program within the automated gadget. It is ideal for batch production procedures where the volume of products is between high and medium. However, redesigning and altering the system for a new arrangement for operations of products can be difficult and requires a lengthy organization. Gadgets which fall under this category include; universal robots, numerically regulated machines, steel rolling mills, and paper mills.

- Soft Or Flexible Automation

This automation structure offers automatic regulation equipment which provides flexibility to facilitate modifications in the product design. Human operators provide codes which are then translated into commands. These facilitate fast execution of the changes. With this type of automation, manufactures are able to produce numerous products using different fields as a joined sequence, as opposed to separate. Some gadgets found in this category include; multifunctional CNC machines, automobiles, and automatic guided vehicles.

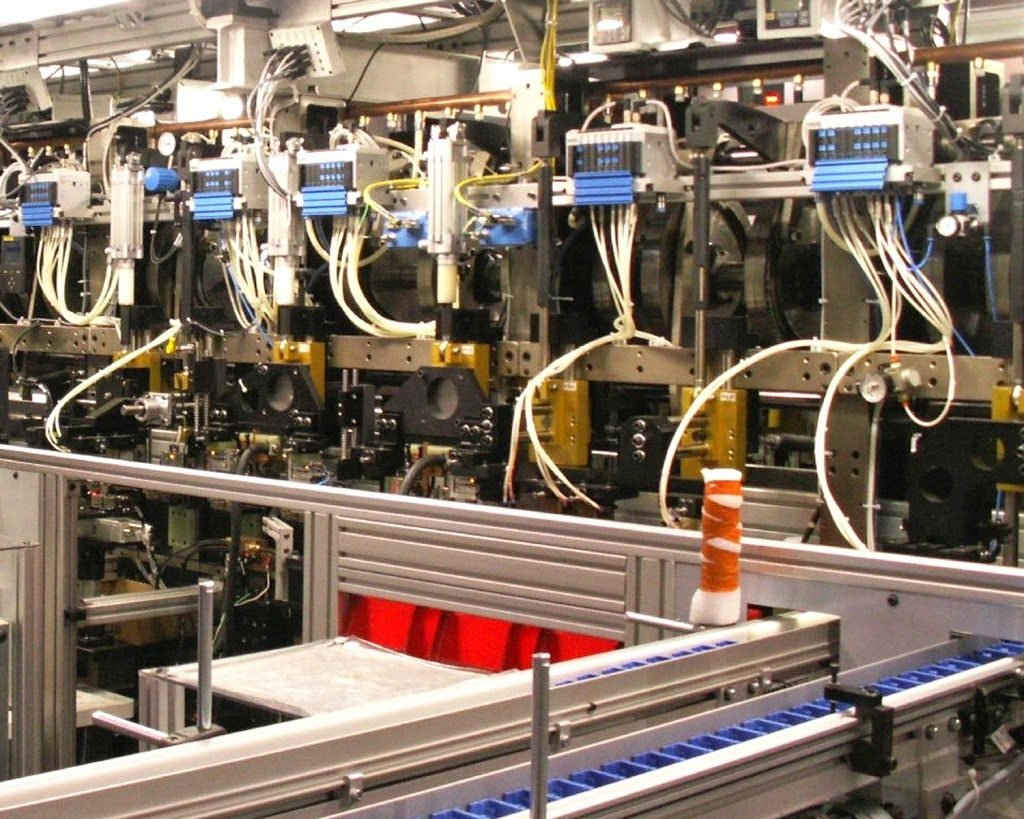

- Hard Or Fixed Automation

This automation involves executed repetitive and fixed operations aimed at increasing production rates. It utilizes dedicated gadgets or exclusive principal to automate process operations or fixed progression assembling. While it does not offer product variety, it lowers unit cost and enhances efficiency by increasing the production rate. Some of the automated systems in this category include; conveyors and paint shops.