The advancement in technology has transformed different industries, including warehousing. The Internet of Things integrates warehouse equipment and with computer systems and this simplifies the operations in a warehouse.

Experts have pointed out that the number of warehouses that use technology in their services is likely to increase significantly in 2020.

You can contact JD Edwards Managed Services if you need services to streamline processes in your warehouse. The following are some of the top technologies that are expected to transform warehousing in 2020:

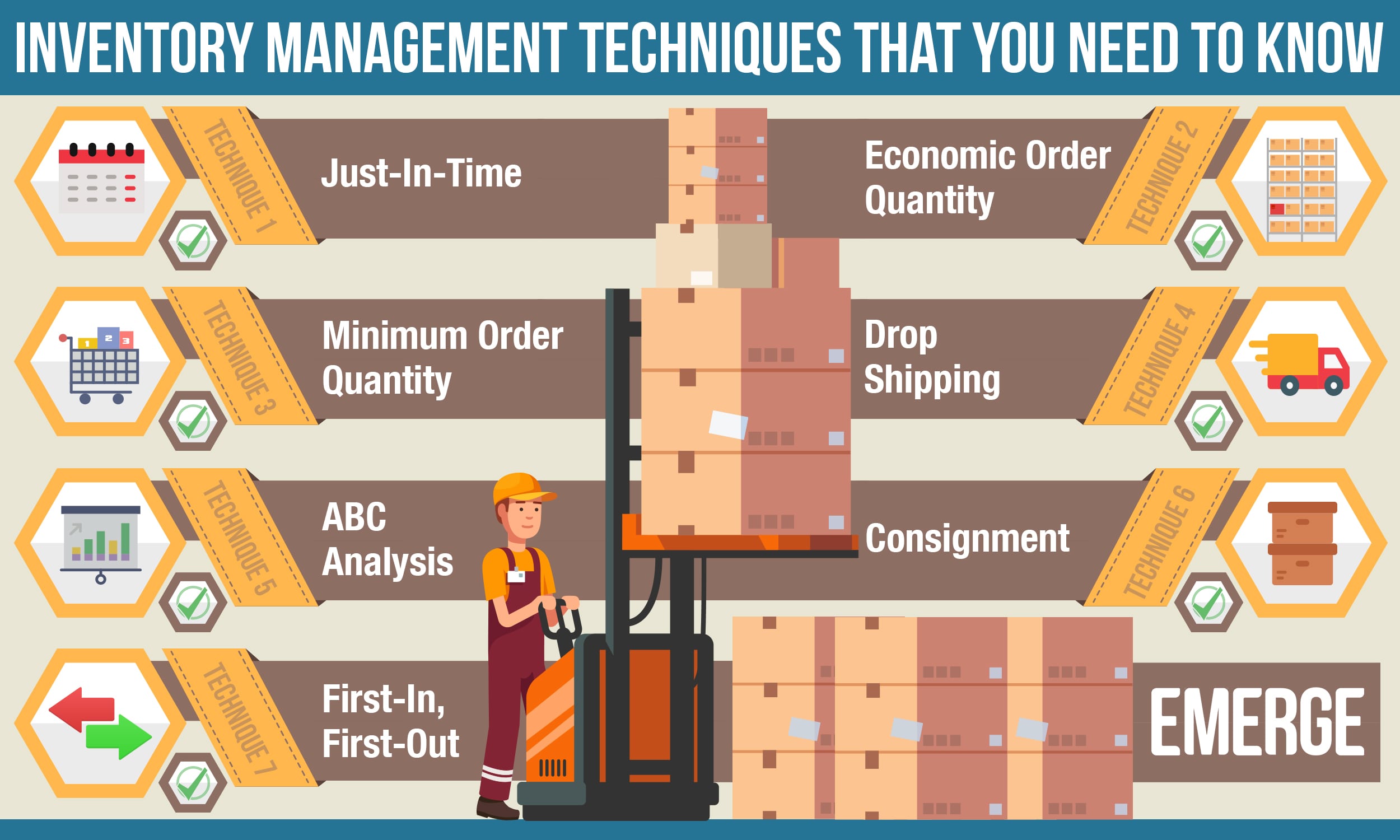

1. End-to-End Inventory Management

The technology helps customers and different companies to track the movement of goods from the moment they are loaded in a warehouse facility and when received by the customers. Without the inventory management system, a lot of time can be wasted when trying to locate products in a warehouse.

An end-to-end inventory management system improves visibility into the business processes, and this facilitates data processing for better decision making. It also leads to increased productivity, and this earns a firm a competitive edge in an industry.

End-to-end inventory management systems provide employees with real-time information about the location and condition of goods, and this helps them to understand all the stages in a supply chain.

The system improves the customer experience from the manufacturing stage until they are received by the customer and hence higher returns.

An end-to-end inventory management system improves efficiency and reliability in product delivery. It enables warehouse managers to define and plan for the delivery of goods from the manufacturing stage and hence increased productivity.

One of the common problems for organizations that deal with fast-moving goods is out-of-stock situations. However, with an end-to-end inventory management system, companies can deliver ordered products to their customers where they need them, and when they need them.

2. Vision and Voice Picking in Warehouse Management

Vision picking involves picking ordered goods out of inventory efficiently. The picking consists of the application of augmented reality in the supply chain.

The concept is gaining prominence in warehouse management as it has numerous benefits, including increased productivity and accuracy among employees. Improved efficiency when picking ordered goods leads to high customer satisfaction levels.

Unlike in the traditional picking where paperwork is required, business owners with vision picking technology can save a significant amount of their time and manual efforts. In manual picking, items cannot be picked efficiently, and employees can make many errors during their work.

Smart glasses are used for voice picking. The lenses have features that enable them to sense an employee’s location in a warehouse facility. Developers of the technology have run pilot projects in Europe and the United States to test its efficiency.

According to the inventors, using technology leads to a significant improvement in accuracy when picking items and increased productivity.

With a voice picking software, employees in a warehouse are only required to wear a headset which allows them to communicate with the warehouse software to confirm and receive ordered goods. According to statistics, the use of voice picking technologies helps to improve productivity during the process by more than 50%.

However, one of the drawbacks of using the software is the high costs associated with implementing the technology, which is estimated to be twice the amount required to achieve the pick-by-paper system.

3. Automation in Warehouses

Automation of different processes in warehouses is gaining prominence in different parts of the world. The process leads to improved efficiency and productivity in a supply chain.

According to supply chain experts, automation cannot solve all the problems in warehouse management. The technology used for the automation of different processes depends on the type of warehouse.

According to statistics about operational expenses in a warehouse, 65% of the costs cater to labor costs. Automation requires a substantial amount of money, but it is cheaper than the continued payment for labor. One of the techniques that are used in automation is robots, which can lead to 100% efficiency when picking goods.

Before you determine the right automation for your warehouse, you should identify the inefficiencies in different warehouse operations once you identify where you need to make improvements, select the automation that will guarantee better returns on investment.

It is advisable to adopt an automation technology with the same capacity as your inventory. Barcode automation technologies are used to speed up scanning of ordered items.